Understanding the behavior of materials in their environment

During their life cycle, the properties of structural materials change. Their implementation involves thermochemical and/or mechanical processes. This induces initial stresses and even which is also influenced by early physical-chemical and mechanical loading. During the service life of the structure, the materials continue to evolve under the effect of environmental actions and mechanical stresses. In modern structural design codes, the service life of structures is defined as the period of serviceability. In an engineering approach, this implies to control the ageing of materials or their durability, so that they provide the structure with the expected level of reliability throughout its life. Taking into account the social issues associated with the various stages of the life of materials and structures implies innovations or even technological breakthroughs (link with the TRU “Green engineering approaches”), in the composition of materials used (low-carbon materials, recycled materials, biobased materials, etc.) and processes.

The objective of the TRU Processes and durability of materials and structures (DURPRO) is to understand and predict the evolution and life span of existing and future structures. Its originality consists in studying the relationships between the composition, the implementation processes and the durability of materials. The approaches developed in the TRU are based on experimentation and modeling and consider in particular the couplings between physical-chemical and mechanical stresses.

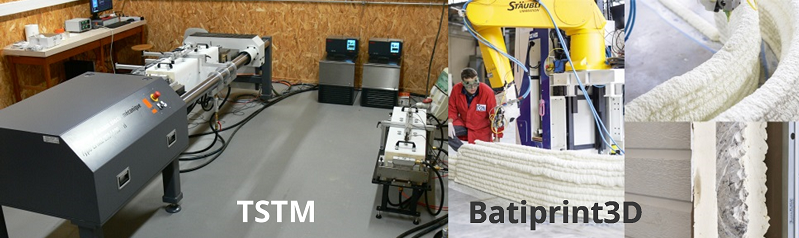

Design, characterization and implementation of materials

In-service behavior, durability and lifetime

FIELDS OF APPLICATION

- Civil Engineering (cementitious materials)

- Aeronautics and naval (composite materials, assemblies)

- Marine Renewable Energy – multi-material structures

- Energy production, transport and storage infrastructures

ONGOING PROJECTS

- Chaire Faurecia 3 – Industrial Composites Chair for Automotive Applications (2022-2027)

- WEAMEC Inter-Mer – Interfaces acier/polymères exposées à l’eau de mer (2024-2026)

- Carnot MERS E-COMENT – Optimal eco-design of ship structural composite parts manufactured by TFP process (2023-2026)

- ADEME France Atlantique (2021-2025)

- ADEME Velella – Reduction of the environmental impact of floating wind energy (2023-2026)

- ANR CO2NCRETE – CO2 Uptake by Accelerated Carbonation of Recycled Concrete Aggregates – CO2NCRETE (2021-2025)

- MONAMOOR – Monitoring of polyamide mooring lines (2020-2024)

- CEAUCOMP – Modelling of coupling between water diffusion and mechanical loading in composite materials (2018-2021)

- Projet National PERFDUB – Performance-based approach of durability of concrete (and concrete structures) (2015-2022)

- …

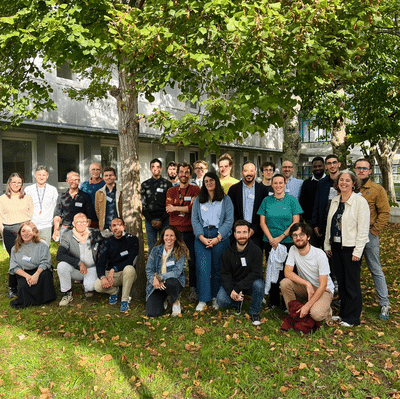

TRU MEMBERS

TRU coordinators : Prof. Ouali Amiri, Prof. Emmanuel Rozière

Members : See GeM directory