During its service life, a structure is subjected to natural or accidental loadings. All of these loadings and the related couplings are likely to influence the properties and durability of structural materials.

Gradients – chemical concentrations, humidity, pressure, etc. – between the material and its environment are at the origin of mass transfers that are often detrimental to the reliability of structures. Indeed, the structural material often also plays a role of diffusive “barrier”. Concrete structures are directly exposed to aggressive agents (CO2, chloride, acid, sulfate, biofilms, etc.), the role of the cover is to protect the steel reinforcement from corrosion. In the case of reactive transport, the phenomenon modifies the chemical composition and the microstructure of the materials (dissolutions, precipitations) and even its state of stress. Moisture gradients affect most porous and organic polymers, with shrinkage/swelling phenomena and associated stresses. The study of hygrothermal transfers is thus necessary to understand the behavior of materials and qualify innovative solutions. It is noteworthy to mention a strong coupling with the mechanical field in some materials, for example with the phenomena of mechano-sorption in the case of natural fibers.

At the scale of the structure, the static or cyclic load, and the combination of external mechanical solicitations and/or environmental actions is likely to be even more detrimental – induced damage and cracking accelerate the transport of material towards the vulnerable zones of the structure (corrosion) – but they sometimes mitigate them (healing).

The maritime environment represents a particular interest and aggressiveness for composite materials in the broadest sense – reinforced concrete, fibre-reinforced polymers, biobased materials, membrane structures, bonded assemblies – and is an important issue for the GeM ecosystem, with the proximity of the Atlantic Ocean and the ongoing development of marine renewable energy (MRE).

This axis will be developed in collaboration with the other TRUs, relying on innovative experimental equipment and multi-physics and multi-scale numerical modelling/simulation. The scientific developments will aim at :

– better understanding and prediction of degradation mechanisms,

– rationalizing the experimentation for the study of the long-term behavior of evolving materials with non-linearities: fatigue of synthetic anchor cables and energy transmission cables, creep, cracking and swelling of cementitious and composite materials,

– characterizing the interactions between the evolution of materials, mechanical loads and environmental actions, in order to identify possible couplings,

– developing performance-based specifications for durability.

This approach allows qualifying a material for a given environment based on aging tests and durability indicators. These performance-based specifications will allow the qualification of innovative materials developed in response to environmental and social issues.

Physico-chemical gradients and transport

Chemical (water, chlorides, CO2, etc.) and physical stresses (UV, thermal, fire, etc.)

Hygrothermal

aging

Composites and assemblies,

Ecomaterials

Mechanical

stresses

Long-term behavior

Fatigue, creep, etc.

Couplings

Damage and diffusion, durability

FACILITIES

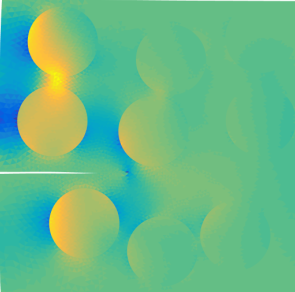

- Numerical methods: numerical and analytical homogenization of physical and mechanical properties, molecular dynamics,

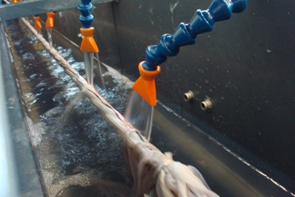

- Accelerated ageing chambers, tidal and salt spray simulator

- Mechanical testing platforms – creep, fatigue, fracture – and associated instrumentation: acoustic emission, image correlation

- Characterization means : microstructure, mechanical and transfer properties of cement materials

- Optical platform

- Microscopic observations: SEM-EDS, microtomography.

ONGOING PROJECTS

- Study of synthetic anchor cables for floating wind turbines (2022-2025)

- MONAMOOR – Monitoring of polyamide mooring lines (2020-2024)

- CEAUCOMP – Modelling of coupling between water diffusion and mechanical loading in composite materials (2018-2021)

- FIRMAIN – Impact of hygroscopic aging on the carcking of composite materials in an uncertain context(2016-2020)

- Projet National PERFDUB – Performance-based approach of durability of concrete (and concrete structures) (2015-2022)