Physico-chemical evolution and mechanical stresses

The implementation of materials generally induces significant microstructural and geometrical transformations. In the case of reactive materials (polymers, elastomers, hydraulic binders, etc.), a set of chemical transformations allow to shift from the liquid (or fresh) state to the solid state to reach the desired mechanical properties and the expected shape. The non-reactive materials (thermoplastic polymers, metals, etc.) are implemented either by fusion or by hot or cold plastic deformation. All these processes are very often associated with temperature changes and possibly with moisture transfers (concrete exposed to drying, polymerization of glue by hydration, etc.). Associated with an evolution of the mechanical properties, these spatial and temporal variations of temperature and water content induce significant deformations and stresses, which are likely to generate damage and cracking.

Ongoing scientific developments conducted in this TRU will include :

– a better understanding of the material structuring and the evolution of its physico-chemical and mechanical properties, during the different stages of the implementation,

– the estimation of the residual stresses field and the risk of cracking after the material or structure implementation.

Experimental and numerical approaches are combined to characterize the couplings. At the experimental level, first-rate equipment and the development of in-situ optical sensors (in connection with the “Measurement and Uncertainty” TRU) among others, allow the GeM to distinguish itself in the advanced characterization of structural materials during their implementation.

Design and characterization of structural materials

New materials, Inovative processes

Implementation of reactive materials

Strain and stress, Couplings

FACILITIES

Experimental methods :

Experimental methods :

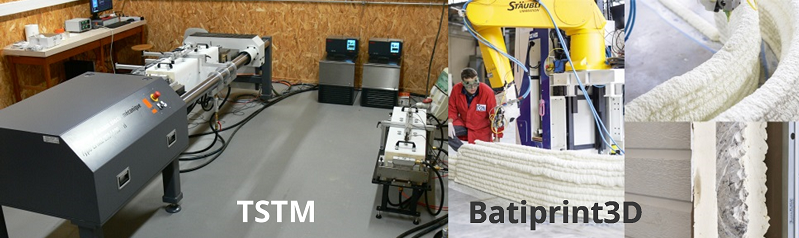

DMA : identification of the material mechanical behavior based on temperature (in HR or possible immersion), Temperature-Stress Testing Machine (TSTM) : study of the short-term shrinkage and creep of building materials- Thermo-chemo-mechanical modelling of an implementation process

- Link with UTR MULTIX – Multi-scale mechanics and physics of materials

ONGOING PROJECTS

- Caractérisation des interfaces de matériaux composites thermoplastiques assemblés par soudage, Noé RESTIF thesis (2022-2025)

- MONAMOOR – Monitoring des lignes d’ancrage en nylon (2020-2024)

- Étude de comportement des matrices cimentaires à base de matériaux recyclés à jeune âge et long terme, Mahmoud Nacer-Eddine HAMDADOU thesis (2019-2022)

- Biocomposites Reinforced with plant fibers: high mechanical performance and durability in a maritime environment, Victor POPINEAU thesis (2018-2021)

- Compréhension de l’état de contraintes internes d’un composite thermoplastique mis en œuvre par enroulement filamentaire, Anna-Maria EL BAYSSARI thesis (2018-2022)

- …